We repair and supply remanufactured and new Oilgear hydraulics – Oilgear hydraulics pumps, Oilgear hydraulics valves, and Oilgear hydraulics motors. Search our online catalog or contact us and let us know how we can help you in your search for Oilgear pumps, motors, valves and more.

It is what we do – keeping Oilgear Hydraulics customers in operation around the clock.

We can supply what you need or repair what you have. Before purchasing a new Oilgear hydraulic unit, there may be a good chance that your current pump, motor, valve or cylinder can be repaired. Oilgear hydraulic pump repairs, including motors, valves & cylinders come with our two year warranty.

When purchasing a hydraulic unit, consider remanufactured Oilgear hydraulics or after market hydraulic units. Best of all they can get you back up and running for less than the cost of a new hydraulic unit. We will give you a free quote so you can compare costs for a new, repaired or reman Oilgear unit, keeping your costs low while providing the Oilgear hydraulic unit you need.

Whether you’re looking for an Oilgear PVWH, Oilgear PVWJ, Oilgear PVWC, or any of the high-quality Oilgear hydraulic units we carry, Precision Fluid Power is your best first stop.

Oilgear Hydraulics History

Founded in 1921 in Milwaukee, Wisconsin, Oilgear hydraulics started manufacturing hydraulic presses for Bucyrus-Erie mining operations. Oilgear was a success from the outset, never suffering a loss, weathering periodic downturns in the economy, including the Great Depression of the 1930s. They gradually expanded product lines from single hydraulic presses to fluid meters, motors, valves for a growing range of industries including lumber, automotive, food, petroleum and chemical. As one of the first companies in the world to use microprocessors with hydraulics in the early 1980s, they began research and development to build complete computer-control systems. They now offer several pumps categories including variable displacement, high-pressure check valve, transfer barrier and injection and catalyst pumps; motion compensation, shot, prefill and exhaust, valves such as screw-in cartridge, subsea and high-pressure valves; accumulators; electronics as amplifier and controller cards.

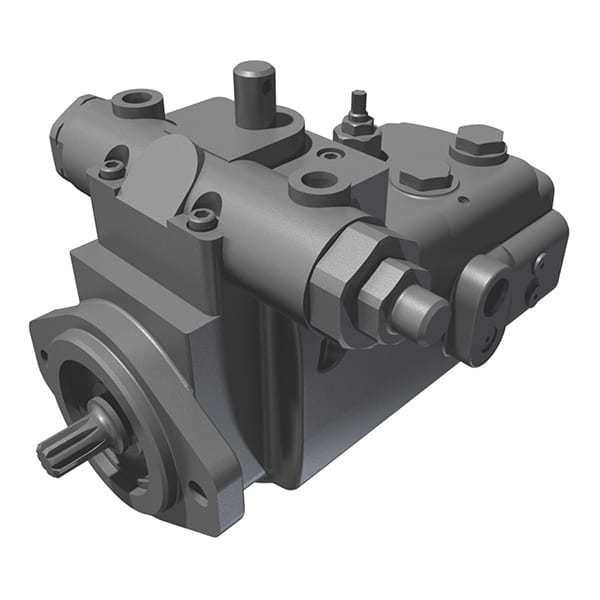

Oilgear Hydraulic Pumps

The most distinguishing component of Oilgear pumps is their patented “hard-on-hard” technology for rotating group in cylinder barrel. Proprietary Oilgear pump offers a greater resistance to contaminants, higher operating pressures as well as the ability to work with low viscosity fluids. Most competitors’ axial-piston pumps rely on load-carrying and mechanical bearings to support the shaft and rotating group. Oilgear pumps utilizes proprietary hydro-dynamic bearing which has no moving parts to wear out which allows for an infinite bearing life. Because there is no concern about contaminating a mechanical bearing, Oilgear pumps can run on a wide variety of tough fluids. Their proprietary hydro-dynamic bearing allows for a sealed front shaft bearing. Advantages include:The most distinguishing component of Oilgear pumps is their patented “hard-on-hard” technology for rotating group in cylinder barrel. Proprietary Oilgear pump offers a greater resistance to contaminants, higher operating pressures as well as the ability to work with low viscosity fluids. Most competitors’ axial-piston pumps rely on load-carrying and mechanical bearings to support the shaft and rotating group. Oilgear pumps utilizes proprietary hydro-dynamic bearing which has no moving parts to wear out which allows for an infinite bearing life. Because there is no concern about contaminating a mechanical bearing, Oilgear pumps can run on a wide variety of tough fluids. Their proprietary hydro-dynamic bearing allows for a sealed front shaft bearing. Advantages include:

- Easy maintenance of shaft seal, shaft and bearing

- Quick conversions

- Operation with any kind fluids

- Can be belt driven

Oilgear Hydraulics Pumps Variable Displacement

Oilgear Variable Displacement pumps convert mechanical energy to hydraulic (fluid) energy. Some pumps are reversible, acting as a hydraulic motor and convert fluid energy into mechanical energy. They provide high horsepower precision control and high pressure in a compact package.

Oilgear Hydraulics Pumps Variable Displacement PVG Series

This series of open loop, axial piston offers high pressure and superior performance in a compact design. They provide an almost instantaneous response to system commands through a high-response four-way pilot-operated control. These pumps feature Oilgear’s advanced “hard-on-hard” technology that provides longer operational life and allows for operation with any kind fluids. The PVG series have five models. Some have maximum continuous pressure up to 400 bar / 5800 psi, up to a speed of 2000 – 3000 rpm.

Oilgear Hydraulics Pumps Variable Displacement PVM Series

Also open-loop, axial-piston hydraulic pumps offer advanced engineering. It is computer-optimized with multiple controls available. PVM pumps deliver high performance in a compact design. These pumps feature Oilgear’s advanced “hard-on-hard” technology that provides a higher degree of contamination resistance and increases the pump’s lifecycle. The PVM series has twelve models with a peak pressure 293.1 bar / 4250 psi. Some models have a speed above 3000 rpm.

Oilgear Hydraulics Pumps Variable Displacement PVV Series

Designed for power and speed, axial-piston hydraulic pumps by Oilgear deliver the punch required for large, heavy-duty systems. The PVV pump line delivers up to 560 horsepower. Pumps are computer-optimized for maximum performance and compact in design with reduced noise levels and improved high-response controls. PVV series offer four models. Some have maximum continuous pressure up to 450 bar / 6500 psi, with top speed of 2000 rpm.

Oilgear Hydraulics Valves/ Screw-In Cartridge

The cartridge valve concept is the modern approach to hydraulics. It is utilized in more installations as hydraulic engineers aware of its excellent performance, design flexibility and substantial savings. There are different valve varieties, sizes and types of valves with extensive size and pressure. Oilgear valves allow for as much fluid as needed, can flow to each function with no concern of high pressure drops, from 1 gpm to more than 300 gpm, with the pressure up to 5000 psi. The Oilgear screw-in cartridge valve line is one of the most complete in the industry. There are hundreds of exclusive specifications available from the 60 original conducts. Components are heat treated and honed as required. Steel-on-steel form construction guarantees high performance, utilizing all regular petroleum and synthetic or “high water content fluids”, or HWCF. Most importantly they are field serviceable with standard tools.